1936 Ford Five Window Coupe Street Rod Restoration 2018

January

Air Conditioning Duck Fabrication and Installation

The former owner of this car had air conditioning installed,

however the air flow would only come out of three hoses hanging straight down from

under the dash.

The problem was our feet would freeze, and the rest of

us would be uncomfortably warm on a hot day. The reason for this problem was the

thermostat was also located under the dash, and it would keep turning the air off before

completely cooling the cabin. I was stuck between a rock and a hard place, I did not want to change

the look of the mostly stock Dash however I needed to divert the air flow to the

passengers inside the cabin to more efficiently control the temperature.

My idea was to somehow conceal the air tunnels under the dash. As

you can see from the photo there was very little room, and a lot of devices that

needed to be worked around.

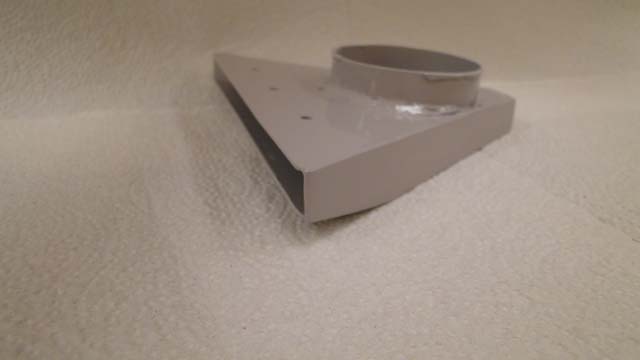

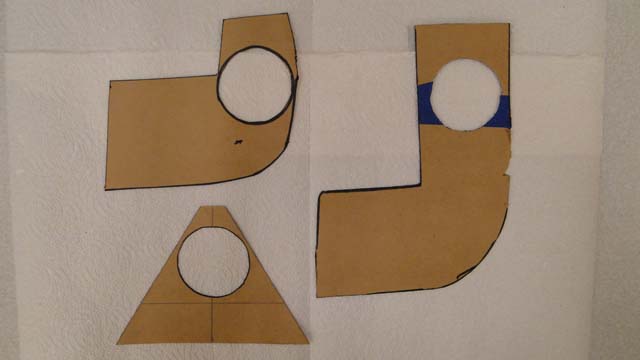

First I had to cut a cardboard template for a test fit,

under the Dash where the air hoses were hanging down. Next I needed

to cut the metal to match my cardboard templates. Then I used large

nuts for the air tunnel spacing. Each of the three vent tunnels were

completely different, which made fabricating them very time consuming.

Then I had to choose between welding or gluing the metal vent tunnels together,

I went with Fuser adhesive for this project. After the glue dried, I

grounded off the ruff edges and

excess glue.

I had to use wire ties over the hoses to secure them to the tunnels hose

gateways, then

screw the tunnels on to the bottom of the dash. Last but not least I

covered my access holes with rubber caps for that professional finish. Look closely you can hardly see

the vents under the Dash.

VDO Digital Speedometer Problems

For the past five years ever since I purchased this

car, the speedometer never worked. In the past it just never seem to

be a priority for me, however last year I started to finish the car mechanically.

In the summer I

tried to configure it, resetting it, and nothing seemed to work as advertised.

I have said this before and I will say it again, nothing

is easy with this car. To remove the speedometer I had to first

remove the dash plate that it was attached to, this is normally no big deal. However the

dash plate was bolted on the dash from the rear and getting though the wiring proved

to be very difficult. With a extendable two inch mirror in one hand to see

the dash plate nuts, and my air wrench in the other I was able to finally remove

the dash plate. For those of you

that don't realize how difficult this is to do, remember when your working with

a mirror everything is opposite to move left you have to move right and up is

down and so on.

Once the speedometer was removed I called the very nice people at VDO and they

recommended Paul at Lauderdale Speedometer and Compass out of Florida for

the service work. I sent Paul my Speedometer and they tried to test it. See

first photo.

To their surprise my unit was completely dead they could not retrieve any

configuration or mileage data from it. Paul then sold me a brand new

speedometer that kind of matched the faces of my other devices, and could connect to my

existing wiring for a reasonable price. See second photo.

The unit was not an exact a match however it looks good

and we will see if it works this spring.

Mystery Switch

When I was working on the speedometer installation, I

found a three way switch buried in the dash that only had two wires connected to

it. At first I thought it was a hidden kill switch, however after

testing it with my volt meter, I found that the switch was currently in the off

position. I traced one end of the wire to the ignition

switch, and the other end routed to where a electric radiator fan would need

powered. It would seem at some point in the past an electric fan was, or was

going to be installed on this car.

Click any picture to enlarge.

Click picture to enlarge.

Click any picture to enlarge.

To mount the air tunnels I drilled small holes in the

top section for the screws, and larger holes in the bottom section. The larger

holes allowed my screw driver to have access to the top section for the mounting

screws. I noticed that the rear of the larger tunnels needed additional

vertical support, so I added a small flange to the top of the tunnels. This

would allow them to sit on the top of an interior panel. I used body filler to smooth out the sides that showed.

Then primer was applied, and

finally the paint matching the Dash was applied.

Passenger Side

Click any picture to enlarge.

Center

Click any picture to enlarge.

Drivers Side

Click any picture to enlarge.

Front Views

Click any picture to enlarge.

Air Vent Dash Installation

Click any picture to enlarge.

Click picture to enlarge.

Click any picture to enlarge.

Click picture to enlarge.

Click picture to enlarge.

February

Finish Interior And Windshield Garnish Molding

Restoration And Installation

The interior work had to stop a few years back until I decided what to do with

the area above the door windows, windshield interior headliner and side posts, the roof had been lowered

approximately four inches which at the time seemed like no big deal.

You see I was not happy with what was done by the previous owner inside the car.

He did not use the original molding on the windshield or the side post and he made a large trim

piece to go across the top of the headliner that blocked my view of the road when I drove

the car. I needed to come up

with a new plan.

After months of looking every where I found two original garnish post moldings and one

original headliner molding in Colorado. They looked a whole lot better in the

photos before I purchased them. When I received all three parts they were in

really really bad shape, I thought this looks easy enough to put in. When I

tried to test install all three parts, nothing fit. I expected the post

moldings to be to long, however the shape and curves needed changed as well.

The large headliner molding part was 3/4 of an inch to short, at this point I

am thinking "What did I get my self into here"? I removed the homemade headliner

and started to modify the side post moldings to fit. I had to trim the

length and remove a large portion of the lip that goes between the glass and car

so I could bend them to fit properly. See photos

What I think has happened is, and this is just a guess at this point, the

previous owner had to change the windshield post angles to meet the roof four

inches sooner than it was designed. This changed everything and

that's why he made the old headliner molding out of fiber board for the interior

instead of re-using the original parts. First things first I had to hammer

out the dents and waves. Next the headliner molding is not designed

for a electric windshield wiper motor, so I had to cut a hole to accommodate

that.

Finally the headliner molding is too

short by 3/4 of an

inch, so I cut it in half right down the center so I could widen it to fit. See

photo.

I had great success with Fuser adhesive on the air conditioner vents, so I

decided to use it again for this project.

I added a little filler to blend the posts with the

headliner, and we seem to be good to go for my first ruff fit test.

Once I was happy with the fit it was time to glue both half's together.

Click any picture to enlarge.

Click any picture to enlarge.

March

Console Fabrication

When I went to attach both headliner half's it quickly

became obvious to me that the previous owner did not make sure the wood strips

that the headliner mounts too were parallel with the windshield going across

the car. At this point I had to cut and add more wood strips for the headliner to

mount too. I needed to make up for the missing inch and a half gap difference from the

windshield on the passenger side, an then I could attach the new headliner trim

to the car. Now for the tuff part I

have to find a place for the interior cab light and add a digital rear view mirror, because I really

cant see any traffic out the tiny rear window at all, because I have had a few near

collisions when I was trying to change lanes. This is what has to

happen, I need to fit the the digital screen over top the original Radio speaker area, and

I also need to have room for the dome light. I started with making a mount

for the screen so I could attach it to the headliner molding over top the

speaker hole. Then I cut an oval hole on the bottom of the screen

mounting box for the dome light to fit into.

Click any picture to enlarge.

Now I needed to test fit the monitor mount to the headliner molding, and then

mount both of them on the car. Before anymore paint preparation is

done. As you can see everything looked great on the inside, wait not

so fast when I went around the front of the car there was a gap between the

headliner and the garnish molding. This is where the original rear

view mirror mounted and would cover this area up. Now this is an

unexpected problem. I have decided to continue on with disassembling

of the console and start painting anyway. I will deal with this

later.

The monitor console came out great, and the garnish moldings look just as

good if not better than I expected. While the paint was drying, I

went to work on the reproduction sun visors, that I had purchased.

I thought I would get fancy and add a lighted makeup mirror in the

passenger side sun visor. So I purchased an inexpensive GM

lighted makeup mirror and welded two rods for it to clip on to, and then

I had to figure out a way to power the light in the mirror as it is

designed to be powered by contact springs that I don't have.

So I soldered both wires directly to the electric contacts, and in

testing it worked just fine.

Click any picture to enlarge.

Click any picture to enlarge.

April

Rear Camera Mount And Wire Installation

My next problem is the camera mounts to the license plate frame,

and I have to move the license plate from the left side of the car to the

middle, in order for the camera to have the correct

orientation. The first issue is I have to make a mounting

bracket and paint the old license plate holder before reinstalling it. Just to

be safe I made one mounting holes larger to allow for final level adjustment.

Now for the easy part or so I thought, the camera mounts to the license

plat holder and I have to run the power and signal cables back though the

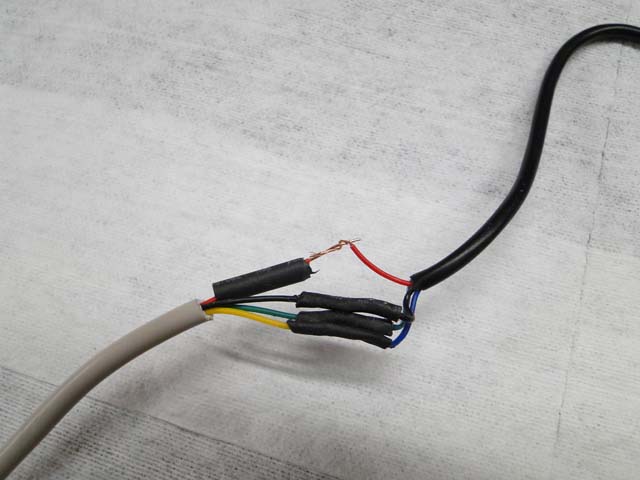

firewall. Then connect the camera to the monitor wiring harness under the dash. Their is only

one problem the camera cable has a large plastic molded end that will

not fit through any of my firewall holes see first wire photo.

The

plastic molding is more than 3/4 of an inch round, with no other option I

had to carefully grinded the plastic away with out damaging the wires

inside,

so it would fit though the firewall hole. See second wire photo

Dash Paint Repair

During my test fit work on the garnish moldings, I accidently scratched

the dash where the two metal parts are connected. The paint repair

had to be completed before I could mount the new headliner and console

in the car. Well this was a

major ordeal to fix as I had to literally cover the entire car with

plastic to protect

it from the overspray when I touched up the paint on both sides of the

dash.

Camera And Monitor Installation Part 1

Now that the dash paint repair is complete I can start the camera,

console and wiring installation. The first problem I ran in to was

the plastic monitor mount that holds the monitor in the console failed

where the mounting screws pass though it. I mean I may have

over tightened them a little bit but the screws went right though the

plastic. At this point I

needed to reinforce the back of the monitor mount with a piece of sheet

metal. I glued it to the plastic monitor mount so the screws

would not pull through. I now needed to run wire for the

dome light, sun visor makeup mirror, and of course the monitor.

In order to prevent the dash from getting scratched again I added a

rubber gasket to go between the dash and the garnish molding. See last

photo.

The first power on test of the HD digital rearview mirror was not completely

successful, it would seem I mounted the rear camera upside down. Once I corrected the

camera orientation I was good to go. Then I was thinking, this HD monitor has a second

video input port for another device, and what could I use that for?

It would be a shame to waste the second video input port. I wondered if I

could connect my IPhone to it?

So I did some R&D and came up

with a wireless based system that would display my IPhone to my HD monitor.

This will allow me to show my phone screen, GPS, movies, videos, just about anything

from my phone will be displayed on the overhead HD monitor.

After I connected the MiraBox device, the second video input screen

worked fine, but now we have a sound issue now, I could barely hear the

music on my speakers. That means I need a amplifier to allow

me to hear the music at a decent level. Great so I purchase

an Alpine AMP and now we have sound, actually way to much sound you see

the sound volume is controlled by my Iphone that has to be synced up

before it can take control of the sound volume. What I end

up with is the sound starts out at full blast until I can turn it down

with my Iphone, this is not good at all. So I looked for a

volume control that I could install between the AMP and the MiraBox device to control the volume then I mounted it in the glove box

where we could have easy access to it.

Click any picture to enlarge.

Click any picture to enlarge.

Click any picture to enlarge.

Click any picture to enlarge.

May

Transmission Seal Leak Repair and Gear Indicator

Installation

Last year Jim at Boffo Motors replaced the standard transmission pan with a larger

capacity unit. When the work was completed we discovered the

transmissions front seals were leaking. There just was not enough time to

do anything about it before the next snow fall. So Jim and I agreed

to address this next spring, which is now. Jim removed the

transmission replaced the front seals and with my help "Ha Ha" we reinstalled the

unit back into the car.

Another issue with this car from day one was it had no gear indicator, when you

went to put it in gear you had to count the clicks and guess what gear you were

in IE one click was Reverse, two clicks was Neutral, Three clicks was Drive and

so on. So I purchased a Locar LED boot shift

indicator that Jim also installed all the lower transmission parts too. Then

it was my job to perform

the wiring under the dash and fabricate a custom metal gear shifter boot mount.

At first I was going to make a basic rectangle shifter base see cardboard

template. Then after the sheet work was already done I thought this

is boring! So I decided to add some curves and make it higher to

give it a little attitude. I had to hand bend the horizontal curves,

and use fiberglass to mold the top angles and filler to finish it off. When that was all done it was

time for primer and paint. The next problem is the interior color

below the dash is grey. So I took a piece of material and had Mark at API, work

his magic on a color match for the boot mount paint. Mark has never let me

down, the paint color match is perfect.

Click any picture to enlarge.

VDO Digital Speedometer Problems Part 2

When I drove the car to Boffo motors I noticed the

speedometer was not working again. While we were working on

re-connecting the transmission back up to the engine, I looked up and

saw the speedometer cable sending unit shaft sticking out of the

transmission, and for some reason I don't know why, I tried to spin it,

and I thought boy that spins real nice. Hold ON! not so fast

that's is not supposed to do that, it should be connected to a gear in

the transmission, and it should only

spin when the wheels turn. So I removed the sending units housing and

inspected the gears, I found no wear and both gears looked good, then I

determined that if I added a washer to the inside of the shaft, it would move the gear further in

to the transmission, and then

the gears

would then engage.

This could be another reason why the speedometer did not work, we will see.

Click picture to enlarge.

Passenger Door Repair

I tried to add extra grease to the passenger door latch for a easer

operation last summer, and it did not help at all. So its time to take

the door apart and see what the deal is, as it turns out the latch spring was

installed incorrectly. I removed the spring and went to re-install it

in the correct position and it snapped in two "of course it did". I did some R&D, and was told that the

1936 Ford early coupes had a small spring, and the later 1936 Ford coupes had

a larger spring. I had no idea which one to purchase so I purchased

both to be safe. Well the small spring is to small and the big spring is

to big. I had to shorten the big spring and re-shape the connecting

end to get it to work properly. After I reinstalled everything the

door open and closes easy, honestly maybe to easy.

Click any picture to enlarge.

VDO Digital Speedometer Problems Part 3

When I drove the car home from Boffo Motors the speedometer still did

not work. REALLY! Now I am pissed, and at

this point I am thinking I need to test everything from the Speedometer

to the sending unit housing on the outside of the transmission and all

its connections, so I started by disconnected the sending unit from the

transmission and spun the gear and the speedometer needle responded

"Well that works". Then I verified that the sending unit

shaft did not spin freely anymore "so that is working too".

I thought the problem has to be right in front of me, but where?

When I was examining the sending unit shaft I noticed it had a

bushing stop that was off center "That's weird". It hit me

like a ton of bricks, and I thought what if the shaft was installed

backwards from day one before I purchased the car, and maybe the long

end needs to go toward the outside of the transmission to spin the

sending unit. Once I did that, it was like magic and it did

not work WTF! I need to walk away and work on something

else for a while, then come back to this

with fresh eyes later.

Click picture to enlarge.

June

Seat Belt Installation

I have never had seat belts in this car, and now that

my kids want to drive her. She needs to be safe. Installing a

three point seat belt system would prove to be to difficult, costly and time consuming,

so I went with a retractable two point belt system that Boffo Motors had custom

made to match my interior. I drilled holes for the one end to mount

to the side frame of the car, and the other side just mounted to the seat.

I also used part of a Velcro strip that I cut in half to serve as a pad in the

belt guide to reduce noise. Nice and simple for a change.

Click any picture to enlarge.

Finish Interior Installation

Now I want to finish the interior, from the windshield

over the doors, and down the side windows. I need to make a

cardboard templates, and then the actual panels. Then we need to cover

the panels, and then finally mounting them.

Click any picture to enlarge.

The Curse Of The Beaver Falls Car Cruse Is Over!

For the first time in over five years this car finally

made it to the Beaver Falls car cruse with out breaking down or acting up. The

weather tried to rain me out, that was not going to happen.

Click any picture to enlarge.

July

Windshield Wiper Modifications

Well I don't know if its OCD or just in my mind, but the front windshield is so

small that the wiper arm and blade seems to take up way to much space, and when

I look down the road to drive I see two wiper blades. Then it

becomes twice the problem. So I though what if I make the wiper arm and

blade removable like on my Austin Healey. I replaced the locking

bolt with a winged bolt that can be tighten by hand. Job done right?

Wait not so fast, when I needed my wiper to work in the rain last week, I turned

it on, the motor ran but the wiper blade did not move. So I though this is an easy fix and went to

tighten the bolt by hand guess what I could

not tighten it any more. Well I have to come up with a new plan.

I disassembled the wiper blade head and noticed I could not get the cast steel

mount point to close tight on the motor shaft when I tried to tighten the wing nut.

I decided to weaken the mount point by cutting a notch on the opposite side of

the shaft hole to allow it to grip the wiper motor shaft better, and it seem to work

just fine now.

Click any picture to enlarge.

VDO Digital Speedometer Problems Part 4

Well I am back on the speedometer problem again, so I called a VDO service

center and sent them photos of the transceiver unit to make sure its

compatible with my VDO Series one speedometer. Hoping that is the

problem and to my surprise they said my transceiver was a original vintage

series one unit and it should be fine. At this point I removed the

speedometer housing from the transmission, and I got a real eye opener the

housing shaft guide was worn so bad that the gear would wobble while spinning.

I replaced the housing and when I went to install the old gear, and somehow I broke

the gear shaft. So here we go again, I purchased a new gear and installed

it and now we have a speedometer that actually works right, wait not so fast.

Now we have a calibration problem which is better than what we had before,

according to my speedometer I was doing 50 MPH in my driveway, and, I was also

doing 110 MPH on the street in front of my house. Once

I get the

calibration problem

corrected I should be good to go.

Camera And Monitor Installation Part 2

This is one of those theory and real life things. I made a bracket

for the license plate frame to mount the new camera to the car, however when I am driving down the

road. I noticed the camera is shaking from the back and forth. Now my plan is to

somehow reinforce the license plate frame with a

steel plate holder from a MGB that seems like it will do the job. I am going to

try and just mount everything from the license frame to the holder and hope I do

not have to do

anything more. When I attached the steel holder to the license plate

frame

it helped a lot but the camera was still moving. At this point I

thought maybe if I reinforced the bottom of the license plate it would stop

moving, so I fabricated a metal rod with a washer at each end for mounting.

Now we seem to be solid and have no movement.

Click any picture to enlarge.

Click any picture to enlarge.

August

Camera And Monitor Installation Part 3

The first time I used this system, If I don't say so my self, this

camera and monitor are way cool, wait not so fast for some reason the

monitor screen is lets just say grainy, real grainy and it also has wavy

lines in the picture to the point for me the system is unusable.

I was a little confused everything bench tested perfect, so I called

Tadi Brothers tech support and they told me I had a power problem

and to check the wires. I check the voltage and it was good,

I ran temporary wires from the battery and no change in monitor quality.

So I called Tati brothers tech support again, and now they said I had a

grounding problem. So I ran not one but two new ground

wires, one at the monitor end, one at the camera end, and no change to

the poor monitor quality. Yet again I called Tadi

Brothers tech support, they sent me a replacement monitor and I

replaced the monitor, still no change in poor monitor quality.

At this point I am becoming very frustrated so Tadi Brothers tech

support sent me a replacement camera and still no change in poor monitor

quality.

I was just about ready to send the whole camera and monitor kit back, when I talked to

Rodger at Tadi Brothers. He said something was interfering

with the camera signal, well now interference that is entirely different

mater. My monster of a motor has an MSD electronic ignition,

so I purchased a line noise reducer from MSD, and my monitor screen

quality was much much better. But I was not happy just yet.

It could be even better I

thought, so I also purchased a Raptor noise filer, and with both

installed the monitor quality was right where it should be with no

interference.

Click any picture to enlarge.

October - November

Under Carriage Lighting

Ok so I had the Ford out for Ice cream one night, and a car pulled in

to the parking lot with lighting under the car that was

lighting up the road. I thought, that is really cool and I want

to do that to my Ford.

I did some R&D on the internet and

came up with the LED lights which were actually not expensive at all.

So I thought how hard could this be? Wow what a mistake that

was, this project turned out to be another nightmare from which I could

not wakeup from. I

have said it before, and I will say it again, nothing is easy with this

car.

Between running the almost fifty feet of wire, soldering the 64 wire

connections for LED's, sealing

each connection with heat shrink tubes, testing and adjusting

the lights for balanced light distribution to prevent bright and dark spots under

the car, and

then mounting the LED lights to frame of the car. If that was not

bad enough, then in the engine compartment I

had to make metal brackets shown in black in the forth photo to mount the LED lights too. I averaged about two hours per LED

light installation time, and

I had 16 LED lights to install.

Then I had to synchronize

the controllers and mount them in a water tight location as well. This took what seem to be

forever to complete, however the lighting effects turned out way better then I

imagined.

Due to the in climate weather, I will have to wait until spring to get

any photos of the lighting effects on this website.

Click any picture to enlarge.

Contact Bob Capo at bob@bobcapo.com for further information

on any of our restorations.Thank You.